- Top: 4Step on: 91

odsysacz pyłów i dymów

People involved | Date:2025-08-16 13:50:59

Related articles

By integrating smoke eaters with automated welding arms, manufacturers can maintain a consistent workflow while ensuring that harmful emissions are effectively managed. This dual approach not only enhances productivity but also aligns with sustainability goals by reducing the environmental impact of welding processes.

Mitigation Strategies

Understanding the various types of container handling equipment is crucial for optimizing your operations. At Yeed Tech Co., Ltd., we provide an extensive selection of equipment tailored to meet diverse handling needs. Our range includes:

Maintenance and Care

Welding fume collectors come in various designs, each tailored to specific industrial needs. Here are some common types

Additionally, innovative technologies, such as advanced coatings and treatments, are continually being developed to enhance the longevity and performance of builders steel. These innovations not only improve the durability of steel but also contribute to more sustainable construction practices by reducing maintenance and replacement needs over time.

1. Enhanced Worker Safety The primary benefit of using a portable fume extractor is enhanced worker safety. By removing harmful fumes from the breathing zone, these devices significantly reduce inhalation risks. This is especially critical in confined spaces or outdoor settings where the dispersion of fumes can be unpredictable.

The Future of Container Handling

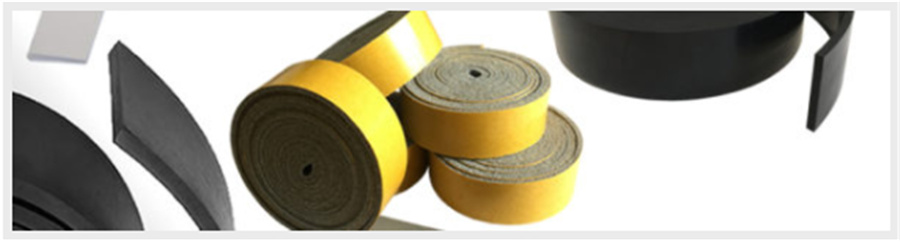

Additionally, it serves as a noise dampener, reducing sound transmission through walls, floors, and ceilings Additionally, it serves as a noise dampener, reducing sound transmission through walls, floors, and ceilings

Additionally, it serves as a noise dampener, reducing sound transmission through walls, floors, and ceilings Additionally, it serves as a noise dampener, reducing sound transmission through walls, floors, and ceilings

Comment area